Hygienic Design as in the Age of early Covid-19

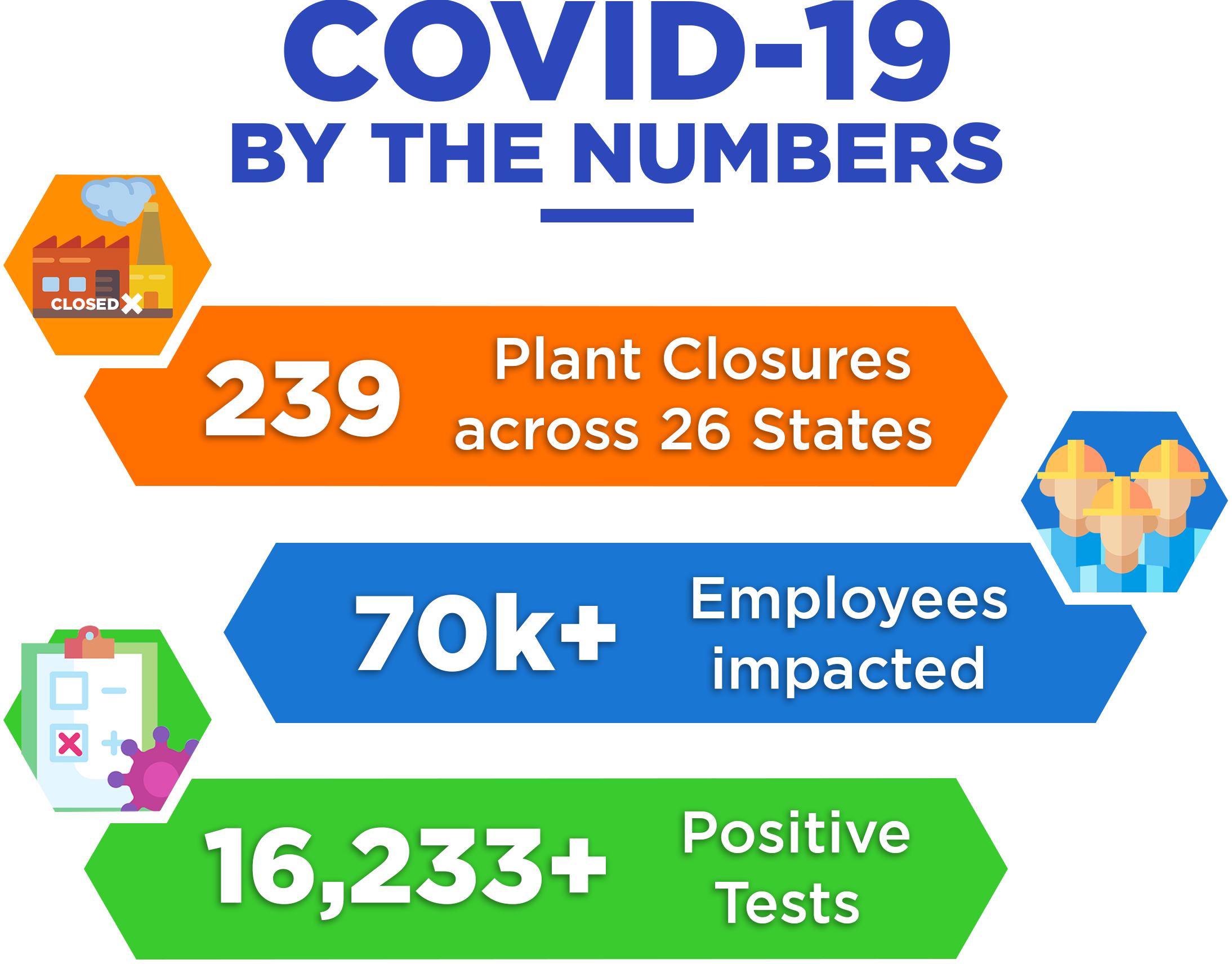

After 239 Plant Closures in the US, Here’s What You Should Know

With nearly 525,000 workers in approximately 3,500 facilities nationwide, meat and seafood processing and packaging are a critical link in the US Food supply chain.

Like everyone in food and beverage packaging, these plants have always had to contend with the threat of germs. Salmonella, E.coli, and other malicious microbes have hospitalized consumers and caused nationwide recalls on products ranging from lettuce to peanut butter. In fact, the Federal Government’s Centers for Disease Control and Prevention estimates there are 128,000 hospitalizations and 3,000 deaths from food-borne pathogens each year in the US alone!

A New Twist to an Old Problem

The Covid-19 pandemic has added a new twist to an old problem. Meat, poultry, and seafood plants are labor intensive operations, requiring many employees to work in close proximity.

The CDC has determined that between from 19% to 88% of employees working in these kinds of high-density environments could be either asymptomatic or pre-symptomatic, meaning they are spreading the virus without even knowing they have it!

View this post on Instagram

Since the virus first made landfall in the U.S. in early March, there have been over 239 closures in meat, poultry, seafood, and other food plants, costing millions in lost revenue, impacting over 70,000 employees and squeezing already pinched supply chains even tighter.

The National Institute of Health (NIH) has found that the Covid-19 virus can survive on plastic and stainless-steel surfaces for as long as three days. Additionally, a recent UK Government study showed that the cold temperatures implemented in plants (normally intended to help combat germs and keep food fresh) may actually prolong how long the virus can live on some surfaces.

Even with a vaccine now in play, employees are coming to understand that good hygiene practices are as much a part of plant safety as earplugs or fall protection. Regular washdown procedures are now not only important for protecting consumers, but plant employees as well.

The Solution

Staggering shifts, plexiglass barriers, improved ventilation, regular testing, and maximizing distances between workers all play a part in keeping employees safe and production humming along, but cleaning continues to be one of the most powerful tools in the plant hygiene arsenal.

Innovative new signage systems akin to traditional lock-out-tag-out, but for cleaning are being implemented. Line workers flip color coded cards to indicate if a work area has been sanitized since the last operator has left. This means that facilities are doubling, or sometimes even tripling, the frequency of their washdowns.

The Negative Impact on Equipment

This extra cleaning is critical to keeping plant employees safe, but what does it mean for the equipment? Most modern food facility equipment is designed with the washdown in mind, but failures can still happen and increasing the frequency of clean-in-place with water and caustics increases the likelihood of an issue.

Plant engineering and safety staff should look for opportunities to enhance “cleanability” alongside other areas of occupational safety. If Covid-19 has taught us anything, it is that we need to prepare for “low probability, but high impact” events.

In any given year, the odds of a global epidemic outbreak are very low, but we can see that the consequences are dire enough that preventative measures are worth the investment.

As plant management look at their production lines and try to identify opportunities to improve cleanability and increase space between operations staff, conveyor lines become a natural target for process improvement.

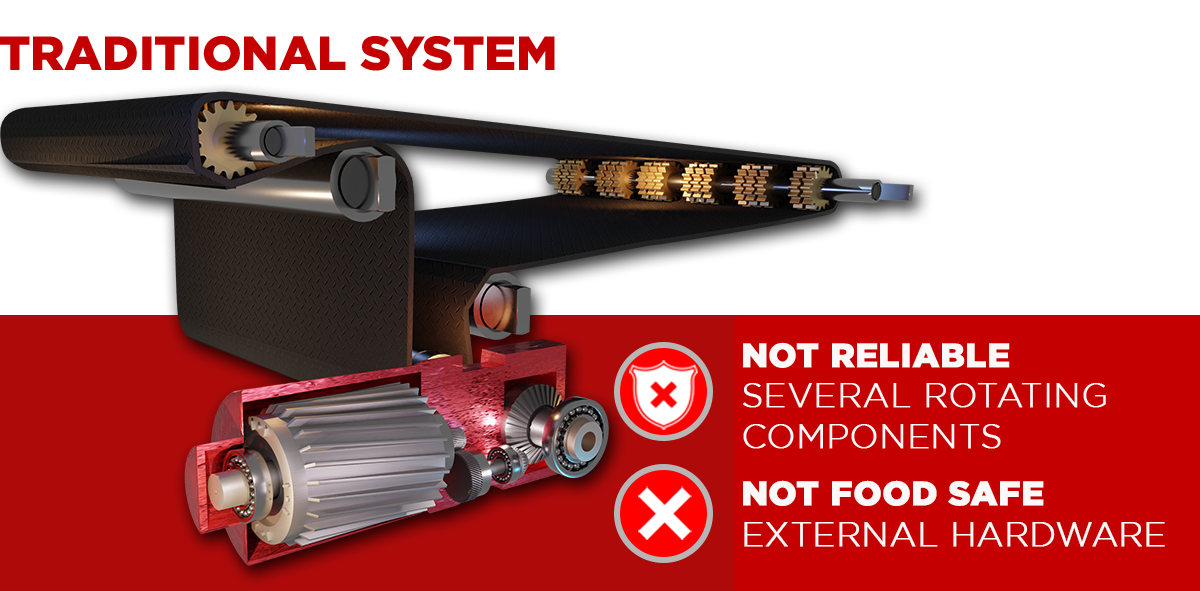

Traditional belt drive systems involve a lot of moving parts. A motor powers a gearbox which often drives a chain connected to a belt roller. These external components make for an easy hiding spot for bacteria and food debris.

While each of these components may have comparatively low risk of failure from cleaning related damage on its own, when you combine the increased risk from more cleaning and the increased cost of having the line go down, then investing in additional preventative measures starts looking like a smart choice.

Make Washdowns Quick & Easy While Reducing Risks of Downtime

Among the many benefits offered by One Motion’s line of direct drive products is the cut shell and elimination of external components. This means a more reliable system along with quick and easy washdowns!

Converting conveyors to washdown friendly direct drive technology can be an efficient and cost-effective way to improve the cleanability of your existing line, much less invasively than other kinds of equipment upgrades.