Energy Efficient

2120 Town W Dr, Rogers, AR. USA

2120 Town W Dr, Rogers, AR. USA

Build A Mag-Drive / Learn more about in-stock products - configure and ship 10 days or less.

Get a specialized quote prepared for your specialized needs.

Request parameters and troubleshooting information.

Find new ways to offer direct motion to your clients.

On average our end users report a considerable amount of savings when compared to legacy solutions.

Learn more about One Motion products

Consume Up To

Less Energy

Produce Up To

Lbs. Less Carbon

Achieve Up To

Energy Efficiency

Gain Up To

More Service Life

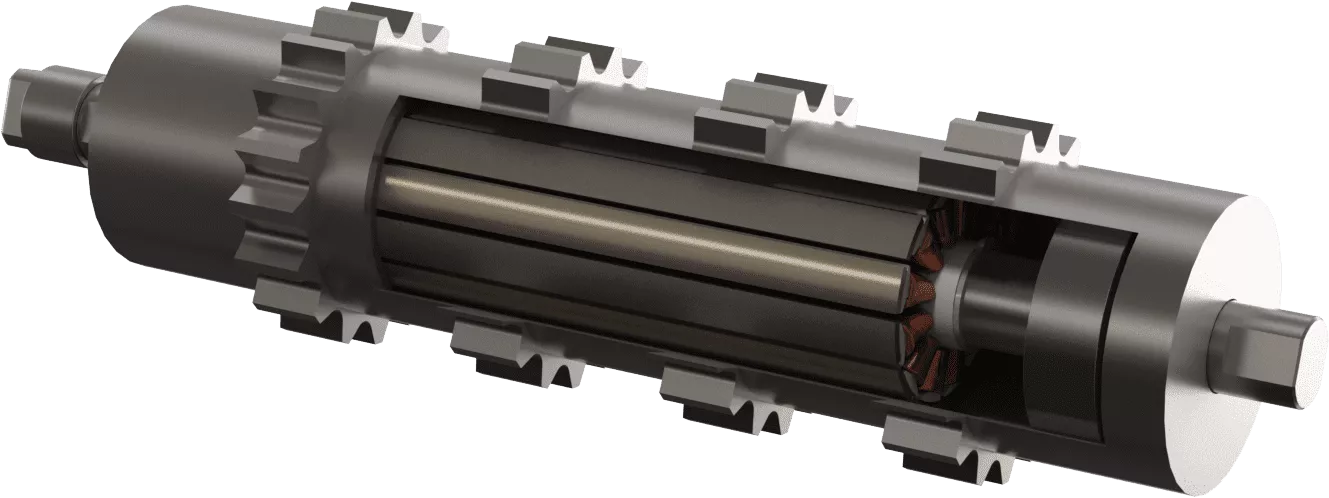

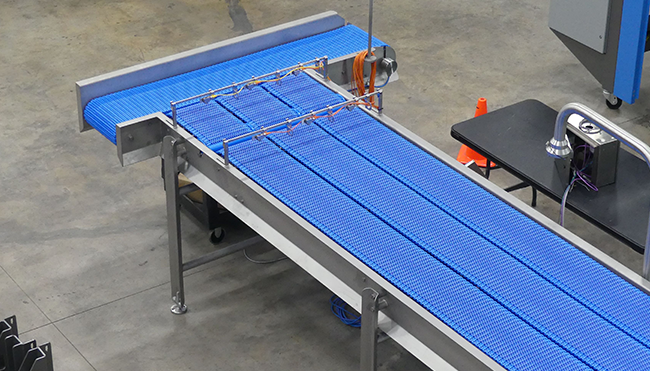

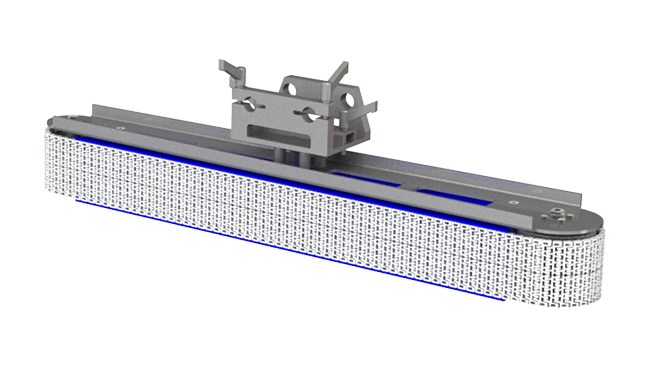

Servo & Legacy Drum Motor Replacement

Drop-in replacement for legacy drum motors.

Reliable servo like motion, speed and timing control.

Compatible with all permanent magnet mode capable VFD models.

Custom shell / sprocket profiles designed for all popular belt types.

Small footprint builds made possible by magnetic direct drive technology.

Backed by an industry leading 3 year warranty on all products.

Mag-Drive Solutions can be dropped or bolted into place. Operated by using most popular Variable Frequency Drives

Direct motion removes the need for grears, reducing maintenance downtime and increasing electrical efficiency.

Mag-Drive is an excellent solution for sanitary applications becasue it has no need for oil librication. IP69k washdown Safe.

One Motion Mag-Smart technology is suitable for common & complex conveyance applications. Direct Drive Technology increases efficiency and reduces maintenance cost.

We provide base framework software at no cost.

Mag-Smart

With open loop synchronous motion, our powered hubs can precisely control the spacing & timing of product.

Mag-Smart

Mag-Drive merge systems can be designed to fit your space requirements and application needs.

Mag-Smart

Servo motion, without the servo motor. Mag-Drive technology makes things just work. Say goodbye to servos.

Mag-Smart

Small footprint, no oil, placed above the sanitary surface. No extra parts or maintenance.