Direct Drive is the application of force to the final mover. In simpler terms, no transmission, no gear reduction, no gear box, no oil, only the application of electromagnetic force to move the object. In our design, we push the magnets around on an outer ring to drive a hub or pulley.

Direct Drive is the application of force to the final mover. In simpler terms, no transmission, no gear reduction, no gear box, no oil, only the application of electromagnetic force to move the object. In our design, we push the magnets around on an outer ring to drive a hub or pulley.

One Motion, our brand, refers to only one device in motion. The power to push magnets is made by rotating the 3 electrical phases in time with the mechanical motion of the driven magnets.

Reliability! Built in we use two bearings in each device, conventional gear driven assemblies will have more than 10 bearings in each system. That is *+ more bearings to fail.

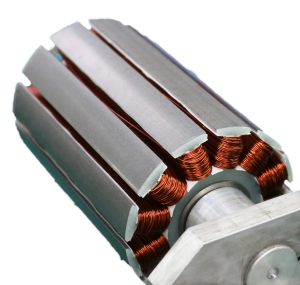

Stator, the name says it all, it is the stationary portion of the powered device. The coils of the stator generate electromagnetic force to push on the magnets.

No special electronics required! Most all industrial frequency/vector drive manufacturers offer a Permanent Magnet or Synchronous Motor Mode. Examples of these are brands you already use such as Allen-Bradley, Yaskawa, Lenze, Emerson, and so on.

No special electronics required! Most all industrial frequency/vector drive manufacturers offer a Permanent Magnet or Synchronous Motor Mode. Examples of these are brands you already use such as Allen-Bradley, Yaskawa, Lenze, Emerson, and so on.

High Pole Count. We use a lot of magnets. You may noticed that our designs do not leave wasted space. The air gaps between the magnets are at a minimum and if you look closely you will see special shaping of the magnets to give us that little something extra.

High Pole Count. We use a lot of magnets. You may noticed that our designs do not leave wasted space. The air gaps between the magnets are at a minimum and if you look closely you will see special shaping of the magnets to give us that little something extra.